Introduction

Polyvinyl Chloride (PVC) stands as a cornerstone material in the field of thermoforming, offering a remarkable blend of properties that make it highly versatile and durable. In this comprehensive guide, we delve into the properties, applications, and advantages of thermoforming PVC.

Understanding PVC: Properties and Composition

Polyvinyl Chloride (PVC) is a thermoplastic polymer derived from the polymerization of vinyl chloride monomers. Its key properties include:

- Durability: PVC exhibits exceptional durability, making it resistant to impact, abrasion, and environmental factors.

- Chemical Resistance: PVC is highly resistant to chemicals, acids, alkalis, and solvents, ensuring longevity in corrosive environments.

- Flame Retardancy: PVC is inherently flame retardant, making it suitable for applications where fire safety is a concern.

- Versatility: PVC is available in rigid and flexible formulations, offering versatility in application and design.

Thermoforming PVC: Process and Techniques

Thermoforming PVC involves heating the thermoplastic sheet to its forming temperature, typically between 300°F to 350°F (149°C to 177°C), until it becomes pliable and moldable. The heated sheet is then formed over a mold or tool using vacuum forming, pressure forming, or twin-sheet forming techniques.

- Vacuum Forming: In vacuum forming, the heated PVC sheet is draped over a mold, and a vacuum is applied to draw the sheet tightly against the mold’s contours, creating the desired shape.

- Pressure Forming: Pressure forming involves the additional application of air pressure to force the heated PVC sheet against the mold’s contours, resulting in more precise detailing and sharper definition of features.

- Twin-Sheet Forming: Twin-sheet forming utilizes two separate PVC sheets heated simultaneously, which are then joined together to create a hollow, double-walled structure. This method allows for the creation of complex geometries and internal features.

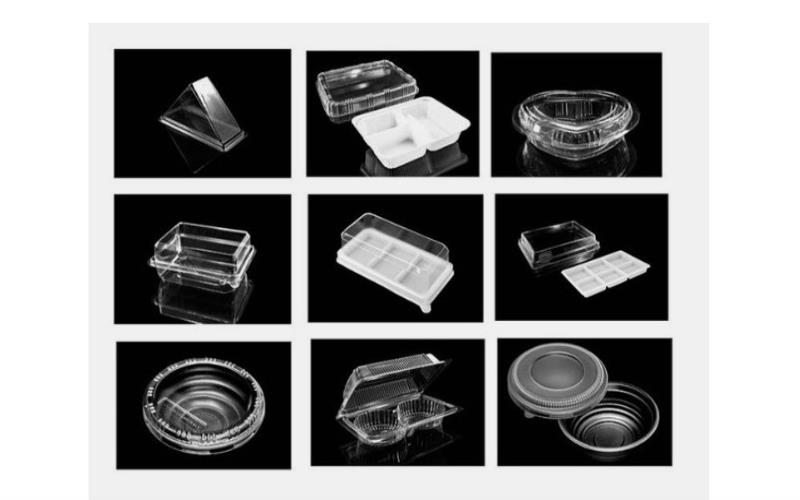

Applications of Thermoformed PVC

Thermoforming PVC finds applications across a diverse range of industries, including:

- Building and Construction: PVC is used in the construction industry for producing pipes, fittings, window profiles, and cladding systems due to its durability, weatherability, and ease of installation.

- Signage and Displays: PVC is employed in the signage and display industry for producing signs, banners, and point-of-sale displays due to its printability, rigidity, and weather resistance.

- Medical Devices: PVC is utilized in the medical industry for manufacturing medical equipment housings, tubing, and packaging due to its biocompatibility, sterilizability, and chemical resistance.

- Automotive Components: PVC is used in automotive interior components such as door panels, dashboards, and trim parts due to its impact resistance, surface finish, and dimensional stability.

Advantages of Thermoforming PVC

Thermoforming PVC offers several key advantages over other materials and manufacturing processes:

- Durability: PVC provides exceptional durability, ensuring long-term performance in demanding applications.

- Chemical Resistance: PVC is highly resistant to chemicals, acids, alkalis, and solvents, ensuring compatibility with a wide range of substances.

- Flame Retardancy: PVC is inherently flame retardant, providing added safety in fire-prone environments.

- Versatility: PVC is available in rigid and flexible formulations, offering versatility in application and design.

Conclusion

Thermoforming PVC offers manufacturers a reliable and cost-effective solution for producing high-quality, durable parts across industries. With its exceptional properties, including durability, chemical resistance, flame retardancy, and versatility, PVC is well-suited for a wide range of applications, from building and construction to signage and medical devices.

By leveraging the unique properties and advantages of thermoforming PVC, manufacturers can create innovative and functional products that meet the demands of today’s marketplace, ensuring customer satisfaction and business success.